1. Installation context and requirements

In 2024, an international water treatment machinery system integrator expressed a need for a cooling system to treat the wastewater of a textile customer based in Dhaka, India.

The objective was to cool process water containing suspended solids (over 700 ppm) from an initial temperature of 45.4°C to an outlet temperature of 35.5°C. The system had to operate in a climate with ambient air at 34°C (dry bulb) and 29°C (wet bulb), providing a thermal output of 2,580 kW. A further key requirement was durability for long-distance transport, given the significant distances involved.

2. Proposed solution

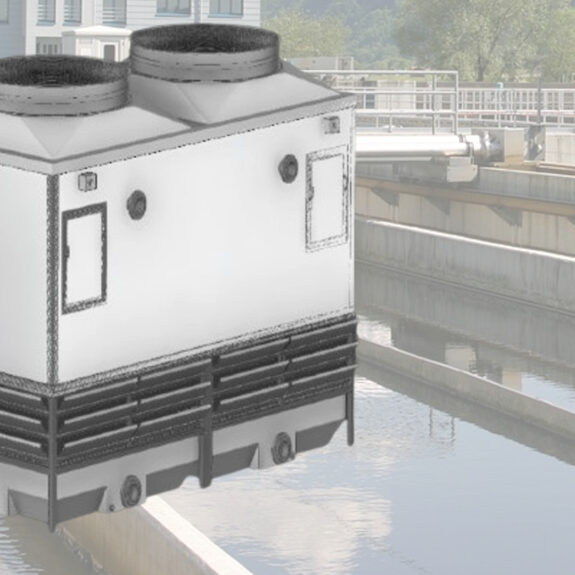

MITA Cooling Technologies supplied an open cooling tower model PME 4804 E CONT GS-ATT, equipped with “Splash” exchange pack specifically for water with high amount of suspended solids. The Container version, selected to meet the need for long-haul transportation, facilitated relocation and installation in Dhaka. The tower body is made of non-corrodible fiberglass, the metal parts of AISI 304 stainless steel: this ensures durability of the system.

In addition, MITA provided consultancy at all stages of the project, from initial design to after-sales, ensuring support and performance optimization for the client at every stage.

3. Results and key success factors

The solution met the customer’s needs for energy efficiency and cooling capacity, keeping wastewater below the required temperature and reducing the environmental impact of the textile production process.

The main success factors were:

- established relationship between MITA and the international manufacturer, which ensured effective and timely communication;

- high-performance and durable solution with the ability to adapt to harsh environmental conditions and specific needs of the textile industry;

- ongoing advice provided by MITA, which enabled design optimization and ensured that the plant met local and international safety and sustainability standards.

Ask for Information