1. Installation context

A store in the province of Vicenza, a customer of a manufacturer and integrator of refrigeration systems, requested an efficiency upgrade of a CO2 chiller. Specifically, the customer’s requirements were as follows:

- increased performance of the CO2 transcritical system,

- reduction of the total electrical energy use of the refrigeration unit,

- reduction of circuit pressures.

2. Proposed solution

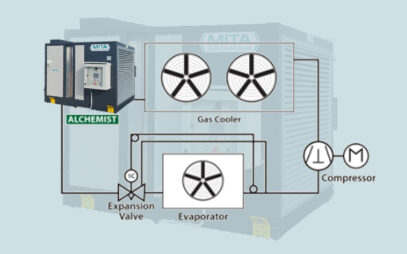

MITA Cooling Technologies, a customer of the system integrator, proposed the installation of an Alchemist model 4000 SR adiabatic subcooler. This plug-and-play solution was easily integrated into the point-of-sale transcritical system, downstream of the gas cooler.

3. Achievements and key to success

The installation of the Alchemist subcooler led to the following results.

- Increased cooling performance: with Alchemist on, the coefficient of performance (COP) is always above 2.2, while with Alchemist off, the COP plummets to values well below 2 during the day.

- Reduction in energy use of about a 27%.

- Reduction in circuit pressures: “average gain” during the week of about 6.4 bar.

Also key to the success of this solution is the combination of two technologies:

- adiabatic cooling, which optimizes water and energy use depending on the time of day and year;

- and subcooling, which lowers the temperature of the refrigerant before it enters the compressor.

The installation of the Alchemist subcooler has enabled the Vicenza store to achieve a significant improvement in the performance of its chillers, resulting in energy and cost savings.

Ask for Information