1. Installation context and requirements

In 2022, MITA Cooling Technologies, in collaboration with its Mexican national distributor Innotec MC, received a request from a multinational company specializing in sustainable filtration to supply high-efficiency cooling systems. The client company, with more than eighty years of experience, is one of the global leaders in filtration technology, present in more than 80 locations worldwide (serving industries such as automotive, energy, water management, and electronics manufacturing).

A Mexico office of the multinational company was looking for innovative solutions to support its production line in Mexico: the customer’s main requirement was the cooling of an injection molding plant for plastic production, a critical process that requires stable temperatures and effective heat dissipation. The outlet fluid had to be maintained at a temperature of about 30°C, with a 35°C water inlet.

‘plant needed a cooling capacity of 1,260 kW. Of course, requirements also included the possibility of transporting system components overseas.

2. Proposed solution

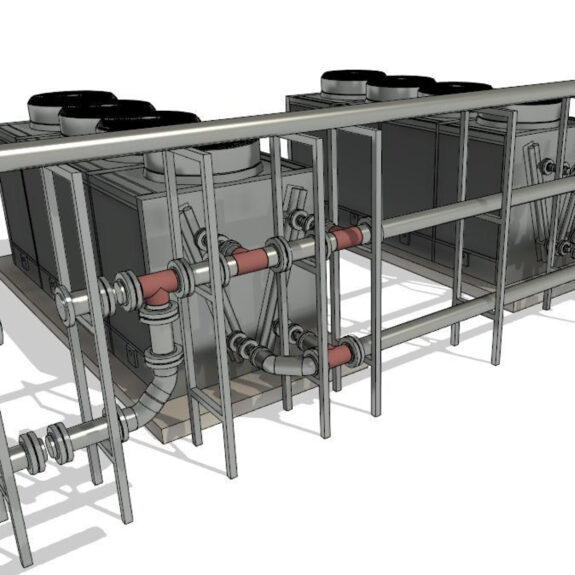

MITA Cooling Technologies supplied two adiabatic dry cooler units model PAD-V H 4/6 Q, equipped with four EC fans each. This technology was chosen for its energy efficiency and ability to operate with reduced water use, perfectly meeting the customer’s requirements for environmental sustainability. The proposed system makes use of an adiabatic flocked PVC pack, a highly impregnable and nonrotting material that ensures strength and durability even in harsh environments. Another key aspect of the proposed solution was the water recirculation kit.

The units are also equipped with a removable wall for internal inspection, facilitating maintenance operations and providing more flexible management of the system.

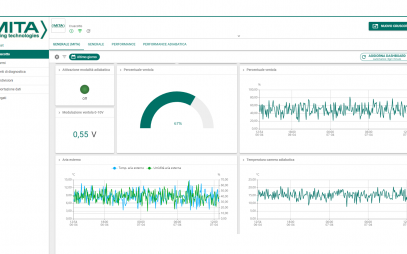

To control and manage the system, MITA has provided the MITA IOT platform-a system that enables remote monitoring and adjustment of chiller operations. This intelligent system allows the plant’s performance to be optimized based on environmental and operational conditions, thereby reducing energy costs.

3. Results and critical success factors

The cooling solution provided by MITA and distributed by Innotec MC to the Mexican customer proved successful for several key reasons.

- First, the energy efficiency of the adiabatic dry coolers made it possible to maintain the required operating temperatures with reduced consumption of water and energy resources. With EC fans and electronic system management, the customer was able to minimize operating costs and improve the overall sustainability of its production.

- n additional critical success factor was the ability to choose from a wide range of cooling solutions offered by MITA, allowing the customer to select the technology best suited to his specific production needs.

- inally, the consulting support and continuous presence of MITA and Innotec MC during all phases of the project, from design to installation, ensured that the system was seamlessly integrated and operating smoothly.

In conclusion, the key to the success of this project was MITA’s ability to offer an efficient and sustainable cooling system that met the customer’s production needs while ensuring low environmental impact and low operating costs. Synergistic collaboration with Innotec MC further ensured that the entire process, from supply to transportation and installation, was executed with precision and professionalism.

Ask for Information