1. Installation context and requirements

In 2024, a Milan-based environmental services company, active for more than 40 years in Italy and Switzerland, sought a solution for cooling new biological treatment lines in its wastewater management facilities. Specializing in the collection, transportation, storage, and treatment of hazardous and nonhazardous waste, this company is committed to environmental protection, developing solutions for waste disposal and contaminated site remediation.

With the goal of reducing the temperature of process water (output fluid) with a 20 percent concentration of glycol, from 43°C to 33°C, the company needed an efficient cooling system that could support a required power of 1,700 kW. A further critical issue: the high load of suspended solids. The total water flow rate required was 146 m³/h.

Given these needs, the cooling had to ensure efficiency and energy savings while minimizing environmental impact and operating costs.

2. Proposed solution

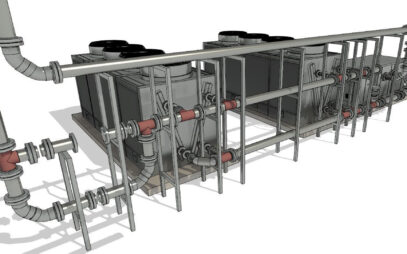

MITA Cooling Technologies provided a customized solution to meet the customer’s needs. The proposal included the installation of two adiabatic dry coolers model PAD-XL-08D-5QW-K1. Each system is equipped with four EC (Electronic Commutation) fans, providing precise control and increased energy efficiency by modulating operation between dry and adiabatic modes depending on load and environmental conditions.

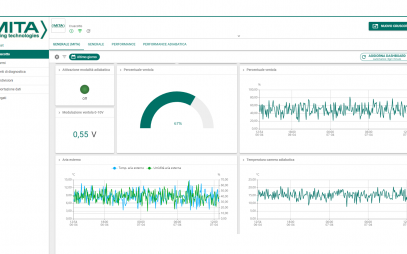

The cooling system has also been equipped with the MITA IOT platform, which enables remote management. With this advanced technology, the customer can monitor in real time and parameterize the operation of the system, thus optimizing the use of resources and reducing energy waste. IoT technology also enables predictive diagnostics and maintenance, increasing the overall reliability of the system and extending the life of components.

To provide further protection against NOx gases in the environment, a special paint cycle was applied to the batteries, further improving the durability of the system in a potentially aggressive environment.

Finally, MITA Cooling Technologies handled the transportation and installation of the entire system, ensuring that the implementation was done quickly and with minimal disruption to the customer’s operations.

3. Results and critical success factors

Thanks to the solution offered by MITA Cooling Technologies, the client was able to achieve efficient wastewater cooling while maintaining the outlet fluid temperature at optimal levels for the new biological treatment lines. The implementation of adiabatic dry coolers ensured high energy efficiency, contributing to significant savings in energy consumption while reducing environmental impact.

The use of the MITA IOT system was critical to the success of the operation, allowing the client to constantly monitor and adjust the operation of the system. The parameterization and control of resources allowed the operation to be precisely tailored to the conditions of use, reducing waste and ensuring maximum efficiency.

Critical success factors of the proposed solution include:

- High energy savings: the ability to switch between dry and adiabatic modes optimizes consumption according to operational needs.

- Remote management via IoT: MITA IOT makes continuous supervision and control possible, improving efficiency and speed of intervention in case of problems.

- Advanced protection: the paint cycle applied to the batteries increases the system’s resistance to environmental conditions, preserving the components from exposure to NOx gases and prolonging the operating life of the system.

Ask for Information