Minimal water use. Short wetting cycles to humidify the adiabatic section, only when necessary. Integrated wetting water recovery kit.

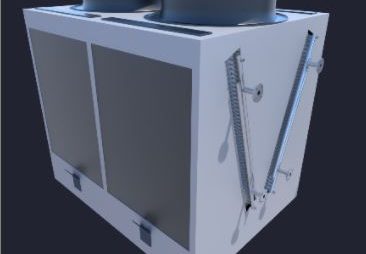

PAD-XL W Adiabatic Cooler

for medium and large plantsIdeal for those who want to use very little cooling water while eliminating its management, or as an alternative to the classic dry cooler, especially with performance in the hottest times of the year in mind.

Energy consumption always optimized. Integrated operation logic (which can also be managed remotely) always optimizes fan operation.

Plug & Play Easy to move, transportable on standard trucks, and quick to install (factory tested and programmed).

No need to manage the wetting water. Simple mains water, no need to treat it, no risk of legionella.

Performance in any condition. Thanks to the adiabatic system and its operating logic, excellent performance can be achieved even during the hottest times of the year.

Simple maintenance. Total, easy and secure access to all essential parts.

How adiabatic cooler works

The adiabatic cooler, sometimes called adiabatic dry cooler or dry cooler with adiabatic pre-coolers, is designed to cool process fluids with ambient air or with ambient air pre-cooled by water (“adiabatic pre-cooling”).

Air pre-cooling generally becomes necessary in hot weather.

Prominent among the various special features of PAD-XL is its integrated operation logic, designed to minimize the use of fountain water, ensuring maximum performance even during the hottest periods of the year. PAD-XL manages and adjusts short wetting cycles only when necessary, avoiding the most common continuous wetting.

Watch the video and learn how PAD-XL W adiabatic dry cooler from MITA works.

BIM files

Download PAD on SkeinforceTechnical features

- Models totally pre-assembled and equipped with electrical panel (PLC allowing continuous optimization).

- Cellulose or flocked PVC humidifier pack (optional) with high humidification efficiency (very short wetting cycles).

- Adiabatic circuit, protected inside, designed to recover water without requiring treatment.

- Dual V batteries.

- EC fans for low electrical usage and noise.

- Support carpentry made of press-bent galvanized sheet metal and then protected with epoxy painting cycle.

- Each machine can be equipped with access for inspection and maintenance of internal parts.

- No risk of legionella and aerosols.

- Thermal duty up to 2,500 kW: 20 fans, 11.6 m long.

Do you wish to know more about our solutions?

Ask for a quote

Environmental and economic sustainability of PAD-XL W adiabatic cooler

- Minimal water use (only for adiabatic operation), which is useful for facilitating heat transfer (i.e., cooling of the process fluid).

- Optimized energy use (higher efficiency due to adiabatic supply).

- Smaller installation spaces compared to the 100% air solution.

- Falls within the product categories that MITA is able to regenerate.

- Indication of “carbon footprint” from the MITA team.

MITA case studies with adiabatic coolers

Adiabatic Dry Coolers for Environmental Service Companies

MITA Cooling Technologies supported a historic environmental services company with an efficient and smart industrial cooling solution. By installing two adiabatic dry coolers and the MITA IOT platform, the client was able to reduce energy consumption and improve wastewater management, all with minimal environmental impact and maximum operational efficiency.

Learn MoreCooler Replacement for a Manufacturer of Porcelain Products in the Netherlands

Significant water savings and a wide range of available solutions-these two factors were key for a Dutch manufacturing company replacing its cooling systems. Two adiabatic dry coolers from MITA Cooling Technologies.

Learn MorePAD Adiabatic Coolers for Ansaldo Energia (Utilities)

One of the most advanced poles for the study of power grids in Europe, in Sardinia, also bears the signature of MITA Cooling Technologies: this is thanks to 13 adiabatic coolers supplied to Ansaldo, among the main implementers of the work.

Learn MoreTools to help you choose

Cooling Advisors

Preliminary plant evaluation

Tailor-made design

Newsletter

Subscribe to MITA newsletter and stay updated on technical solutions for industrial and civil cooling and get to know our offer.