Remote monitoring. The internet of things allows you to eliminate distances and intermediaries with real-time remote monitoring of each of your machines installed in the world.

The history of the device in a single interface. The life cycle of each individual cooler and of the entire fleet is traced on the basis of the real data of their use.

Diagnostics and prevention. Big data allows you to know the actual use and improve the distinctive performance of your already installed pieces of equipment and their future evolutions.

How it Works

Fast edge computing processing and real-time alarm and fault reporting.

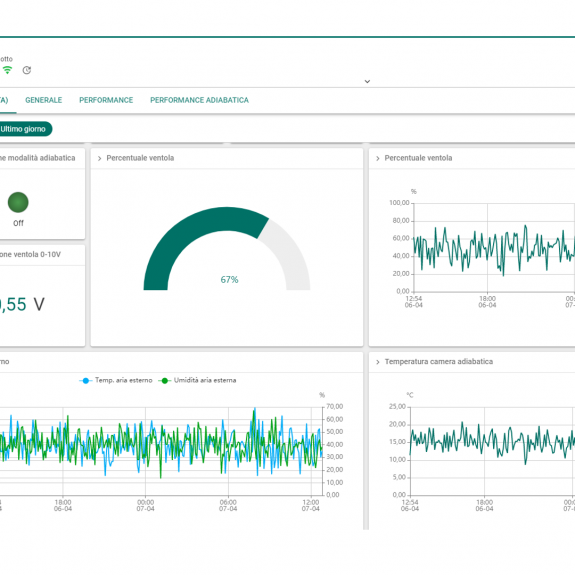

Complete integration of the data collected in the monitoring, diagnostics and analysis dashboards.

Advantages

Performance monitoring.

Real-time monitoring and Big Data collection.

Knowledge and analysis of the lifecycle of the cooler.

Machine management and data sharing.

Diagnostics and prevention.

Downloads

Fonderia Casati is Industry 4.0 also thanks to MITA Cooling Systems

Fonderia Casati, a historic company in Varese, has understood the importance of industrial process automation to maintain its competitiveness at the European level.

Learn MoreTools to help you choose

Cooling Advisors

Preliminary plant evaluation

Tailor-made design

Your Plant Needs

Newsletter

Subscribe to MITA newsletter and stay updated on technical solutions for industrial and civil cooling and get to know our offer.