3. MITA Adiabatic Cooling Systems: cooling liquids or condensing gases

For processes that require efficient cooling of water or other process fluids, MITA adiabatic systems represent a more resource-optimized alternative to traditional dry coolers, primarily thanks to their exceptionally low water usage. Designed to offer superior performance even during the hottest times of the year, these systems intelligently activate their adiabatic pre-cooling only when strictly necessary, also eliminating the need for complex water treatments.

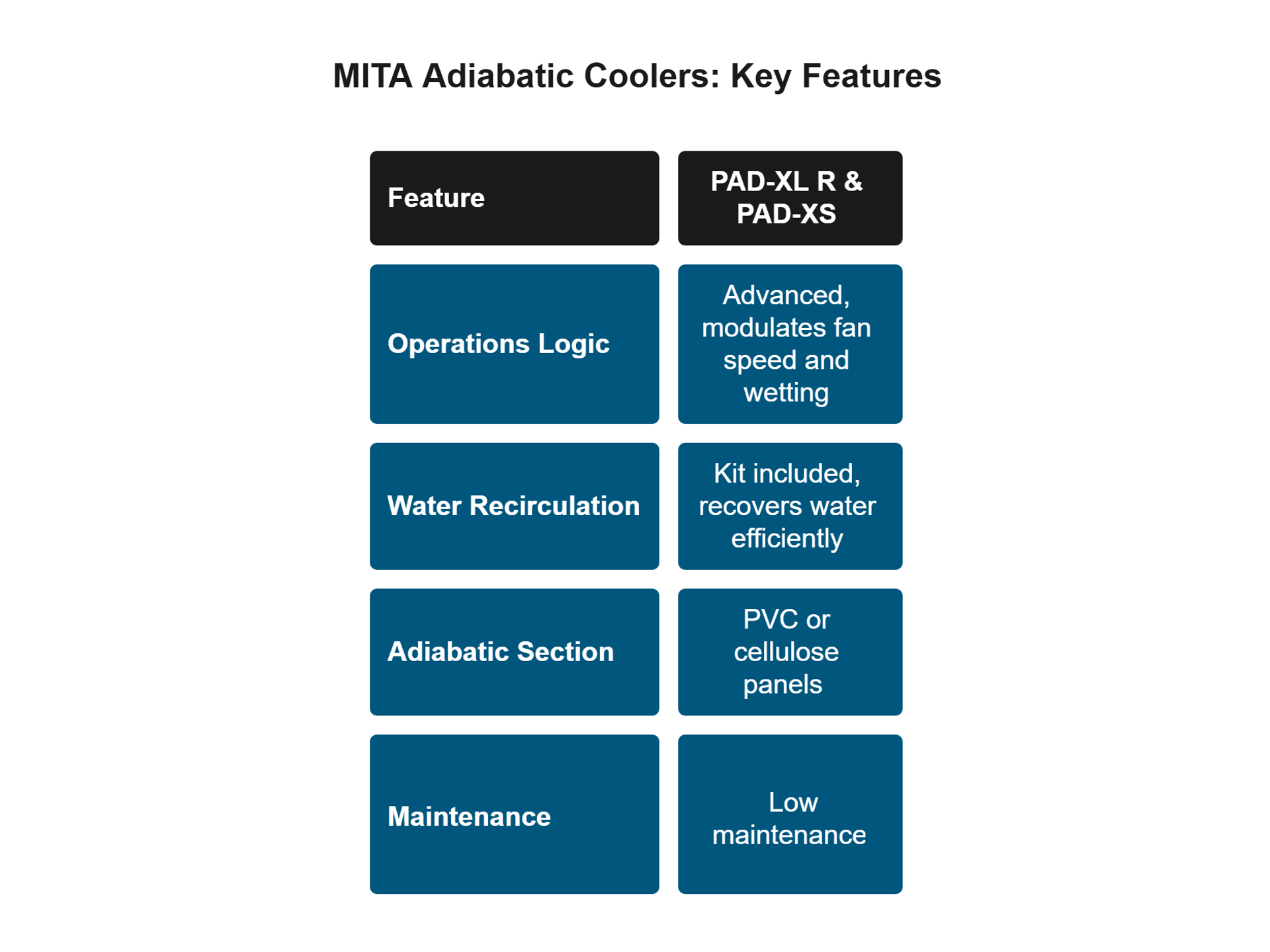

For the heat dissipation of even large-scale systems, PAD-XL W offers thermal capacities of up to 2,500 kW and can be configured with up to 20 fans over a length of 11.6 meters. This system is Plug & Play, ensuring ease of handling and rapid installation. It uses short, on-demand wetting cycles and an integrated system for recovering the wetting water; furthermore, it employs simple mains water that may not require treatment. The operating logic is governed by a PLC that optimizes the EC fans. The efficient design of the V-coil and the humidifying pack ensures high performance and simple maintenance. An ideal cooler for those seeking minimal water use and simplified management.

For small-scale systems, with contained thermal capacities (20 kW to 50 kW), optimized cooling has an ally in PAD-XS: its compact, low-footprint design makes it suitable for limited spaces. Here too, operation is automated with EC fans and regulation of the wetting cycles. It directly uses mains water without the need for specific treatments, with minimal and seasonal usage. PAD-XS is easily integrable into existing systems and, like all MITA industrial coolers, can be designed and configured to support remote control, monitoring, and data collection.

Both models guarantee minimal water usage and optimized energy use thanks to the advanced logic of the control panel. They also require a smaller installation footprint compared to 100% air-cooled solutions. They are regenerable products and contribute to reducing the carbon footprint.

Ask for Information