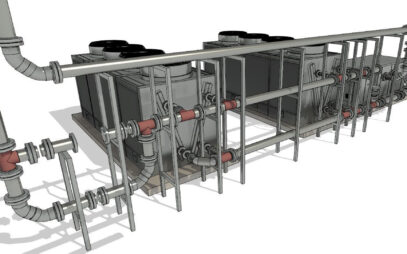

Adiabatic Dry Coolers for Mexican Bottling Company

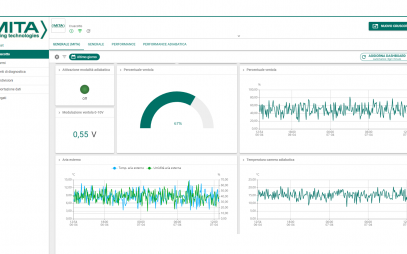

Here's how MITA and Innotec MC helped a large bottling company in Mexico cool its production lines while saving energy and water: three efficient PAD-V series adiabatic dry coolers were installed to provide the efficiency and sustainability needed in a hot environment. The MITA IOT system for remote monitoring ensures that the project combines innovation, sustainability, and attention to the service component in an overseas context.

Learn More