Examples of processes: cooling for foundries, metal and plastic processing, and the food industry.

Cooling Systems for Industry Applications

Industrial cooling systems are crucial to the continuous and safe operation of multiple industries, from metallurgy to food and beverage to oil & gas. MITA Cooling Technologies offers customizable solutions, including open and closed cooling towers, adiabatic dry coolers, and chillers, designed for efficiency, ease of maintenance, and integration with remote monitoring systems. Industrial plants can optimize resource use and improve performance with a view to sustainability and energy savings.

Typical needs: performance, business continuity, energy efficiency, remote control.

Technologies offered: PME-E open cooling towers, MCC closed circuit towers, PAD-XL W dry coolers, Frigofluid chillers, MDC-V and MDC-V dry coolers.

Cooling needs typical of industrial settings

Industrial plants need reliable cooling systems to maintain stable process temperatures and ensure business continuity.

Therefore, industrial cooling plants, or rather “industrial cooling systems,” must be energy efficient, easy to maintain, and capable of optimizing the use of water and other resources. Moreover, with the advent of Industry 4.0, there is a growing demand for advanced technologies that enable remote monitoring and data analysis for predictive maintenance.

Tell us your cooling needs

MITA cooling solutions for the process industry

MITA Cooling Technologies supports industrial cooling with a wide range of solutions, suitable for different production and environmental needs.

PME-E open cooling towers and MCC closed cooling towers offer efficiency and resilience in intensive industrial environments, while PMM and PME-XL modular cooling towers provide scalability and flexibility for large plants. For very large plants, such as those in the oil & gas industry, the answer is a must: field-erected cooling towers from the PU series.

In settings with smaller capacity requirements, PAD-XL W adiabatic dry coolers are ideal for saving water with good performance, where Frigofluid chillers provide precise cooling for critical processes with fluid outlet temperatures near 0°C (or below). MDC-V dry coolers offer another option for cooling with high reliability without using water as a resource.

Evaporative and Adiabatic Cooling: differences

Watch the video and find out moreExamples of industry processes served by cooling technology

MITA’s technologies are used in a variety of industrial processes, including cooling of metal casting machinery, fluid cooling in plastic processing, and heat dissipation in the food and pharmaceutical industries. Solutions are designed to meet the specific requirements of each process while maintaining high levels of efficiency and reliability.

MITA Cooling Technologies is committed to providing industrial cooling solutions that meet the highest standards of quality and sustainability. We work with our customers to identify the ideal solution based on specific space needs, maintenance requirements and environmental regulations. Our solutions are customizable and designed according to the needs of the individual project.

Cooling technologies for an industrial plant: where to start?

If you are looking for cooling technologies for an industrial plant, you need to start with a number of questions, which you can of course discuss with your process cooling consultant advisor.

- Which fluid do you need to cool? Water, gas, other fluid?

- What is the cooling system’s application? Food, metallurgical, energy…

- What is the main FOCUS? Performance, savings, footprint, …

- What are the ambient conditions of the installation location? Wet and dry bulb…

- What is the requested output temperature?

- What and space measures do you need to consider?

- What is the size of your system (and your future cooler)?

- What is the thermal load generated by your plant?

- What services do you need? Total water management, remote management, spare parts, …?

- What level of reliability and maintenance do you need?

- Does the supplier you choose have good references?

- … The other questions are asked by a (good) cooling consultant!

Industrial Plant Cooling: 12 + 1 Things to Consider

Read the article and find out your needsMITA Industrial Cooling Solutions

PME-E Open-Circuit Evaporative Cooling Tower

A light and non-corrodible open-circuit evaporative cooling tower: process industry and HVAC operators will be able to count on its multiple versions and ease of transport and installation.

PMM Modular Cooling Tower

This is a series of large industrial cooling towers for power generation, steel and aluminium processing, cogeneration and other large production sites. Efficiency, high performance, reduced installation and transport costs are granted.

PU Field-Erected Cooling Tower

The PU series field-erected industrial cooling tower can serve very large plants: especially oil & gas, chemical and power generation. Available for all industrial water. Different materials are supplied according to project needs: concrete, steel, fiberglass and pultruded.

MCC Closed-Circuit Evaporative Cooling Tower

Some industries need to keep the chemical-physical characteristics of the process fluids unchanged: in these cases, MCC closed-circuit evaporative cooling tower joins the game. Possibility to work in free-cooling mode. MCC-EC version available with electronically controlled fans.

PAD-XL W Adiabatic Cooler

Ideal for those who want to use very little cooling water while eliminating its management, or as an alternative to the classic dry cooler, especially with performance in the hottest times of the year in mind.

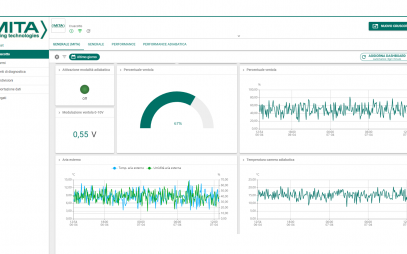

MITA IoT Platform 4.0

Your cooler is transformed into a connected cooler “industry 4.0”: performance, resourse use, maintenance just a click away.

Factory Cooling Solutions: MITA Case Studies

Fonderia Casati is Industry 4.0 also thanks to MITA Cooling Systems

Fonderia Casati, a historic company in Varese, has understood the importance of industrial process automation to maintain its competitiveness at the European level.

Learn MoreCooling Technologies for a High-Quality Food Process

More than a hundred years ago it was an apple orchard: now it is one of the most important food industries in Sweden. This is the company to which MITA Cooling Technologies and CAMPreq have provided solutions-as manufacturer and process cooling consultant, respectively.

Learn MoreExtraordinary water savings for the plastics industry with the MITA adiabatic system

A plastics processing company in the province of Lecco has chosen the PAD-V cooler for the cooling circuit of its production plant: the eco-sustainable system that cuts water and energy bills.

Learn MoreYour Plant Needs

Tools to help you choose

Cooling Advisors

Preliminary plant evaluation

Tailor-made design

Newsletter

Subscribe to MITA newsletter and stay updated on technical solutions for industrial and civil cooling and get to know our offer.