Process examples: electricity generation and heat recovery for heating and refrigeration.

Cooling Systems for Cogeneration and Trigeneration Plants

Cogeneration and trigeneration represent advanced energy efficiency systems, enabling the simultaneous production of electricity, heat and, in the case of trigeneration, also refrigeration. To maximize the performance of these systems, MITA Cooling Technologies offers a full range of cooling solutions: from evaporative towers to dry coolers and advanced chillers, ideal for meeting the specific needs of this sector.

Typical needs: high energy efficiency, reduced operating costs, and sustainability.

Cooling technologies offered: PME-E cooling towers, MDC-V dry coolers and PAD-XL W adiabatic coolers, Frigofluid chillers with Free Cooling, remote monitoring.

1. Typical needs of the industry

The cogeneration and trigeneration sector needs highly efficient cooling solutions to support heat recovery processes and reduce overall energy consumption.

Here are some of the typical needs.

- Energy efficiency: minimize thermal energy loss and optimize production cycles.

- Reduced operating costs: low-maintenance cooling technologies and reduced energy use.

- Environmental sustainability: reduce environmental impact and water use, with systems such as adiabatic dry coolers and chillers with Free-Cooling mode.

2. MITA Cooling Technologies' solutions for the industry.

MITA Cooling Technologies offers a range of systems designed specifically for cogeneration and trigeneration needs.

- PME-E cooling towers: high efficiency and versatility for condenser cooling in plants with high thermal requirements.

- PAD-XL W adiabatic dry coolers: use water only in hot periods through automation of operating parameters, reducing water use and operating costs.

- MDC-F and MDC-V dry coolers: zero water use solutions, ideal for contexts where the availability of the resource is zero.

- Frigofluid chillers with Free Cooling or environmentally-friendly refrigerants: suitable for systems that require continuous cooling and flexibility in energy use.

- MITA Control System: inverter system to optimize performance and reduce operating costs.

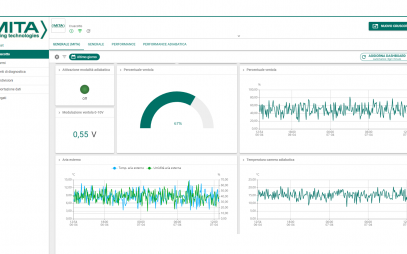

- MITA IOT: remote monitoring platform for efficient management and predictive maintenance interventions.

The adoption of MITA Cooling Technologies’ technologies in cogeneration and trigeneration systems helps improve overall energy efficiency, supporting the sustainability goals of businesses and industrial facilities.

Using the MITA Control System panel and the MITA IOT platform, the operation of cooling systems can be monitored and optimized, reducing the risk of plant downtime while maintaining precise control over resource utilization.

3. Examples of industry processes served by cooling technology

MITA Cooling Technologies’ technologies are applied in some, precise cogeneration and trigeneration processes.

- Condenser cooling for cogeneration and trigeneration: disposal of exhaust steam heat, optimizing energy recovery.

- Absorption chiller cooling for trigeneration: the cooling system (evaporative tower, dry cooler or other) is used to dispose of the water used to condense the refrigerant of the absorption refrigeration cycle.

Cooling Technologies for Cogeneration and Trigeneration

Read the articleMITA Cooling Systems for Cogeneration and Trigeneration Plants

PMM Modular Cooling Tower

This is a series of large industrial cooling towers for power generation, steel and aluminium processing, cogeneration and other large production sites. Efficiency, high performance, reduced installation and transport costs are granted.

PME-E Open-Circuit Evaporative Cooling Tower

A light and non-corrodible open-circuit evaporative cooling tower: process industry and HVAC operators will be able to count on its multiple versions and ease of transport and installation.

PAD-XL W Adiabatic Cooler

Ideal for those who want to use very little cooling water while eliminating its management, or as an alternative to the classic dry cooler, especially with performance in the hottest times of the year in mind.

MDC-V V-Type Dry Cooler

Ease of installation, operation and maintenance–serving even large systems: this is the MDC-V V-shaped dry cooler. The peculiar design of the coils allows a larger heat exchange surface area than table-top dry cooler systems. All in an easily scalable solution.

RW / EFC ax Chiller with Free-Cooling

The RW / EFC ax chiller combines energy efficiency and sustainability for industrial refrigeration with integrated free-cooling technology. The combination of operating modes, between free-cooling and compressor operation, allows up to 80 percent energy savings compared to conventional versions.

MITA IoT Platform 4.0

Your cooler is transformed into a connected cooler “industry 4.0”: performance, resourse use, maintenance just a click away.

Some MITA Projects for Cogeneration and Trigeneration

Cooling Towers for Absorption Chillers in Trigeneration

MITA Cooling Technologies provided an efficient and quiet cooling solution for a trigeneration project, working with a Milan-based energy systems integrator to optimize processes for a major manufacturing brand. Through innovative cooling towers and a trusted relationship with the client, MITA helped create a sustainable, state-of-the-art “hydrogen-ready” plant.

Learn MorePolygeneration at Palermo University

In 2016, the University of Palermo modernized its buildings with a polygenerative solar system, part of the EU-funded STS-Med project. The absorption chiller needed a cooling system.

Learn MoreCooling for a Cogeneration Plant in Poland

High cooling efficiency, more than easy on-site transportation and installation: in 2012, MITA Cooling Technologies supplied a Polish power generation company with two PMM modular cooling towers.

Learn MoreYour Plant Needs

Tools to help you choose

Cooling Advisors

Preliminary plant evaluation

Tailor-made design

Resources

Best practices

Read all Pieces of Advice by MITA Cooling TechnologiesWhat to Know

Find Out All Technical TermsTechnical Articles

Read All our Technical ArticlesNewsletter

Subscribe to MITA newsletter and stay updated on technical solutions for industrial and civil cooling and get to know our offer.