Efficiency increase with "green" refrigerants. Thanks to the combination between adiabatic cooling and subcooling of the refrigerating fluid.

Alchemist Adiabatic Sucooler

to subcool R744 in transcritical plantsPerformance, savings and environmental sustainability thanks to a patented Plug & Play subcooler for refrigeration systems working with R744 (CO2) and fluorinated refrigerants (HCFC, HFC, HFO).

Automatic operations. Intelligent regulation of fans and dampening cycles.

Compact and integrable design. Simple and easily integrated into existing systems.

Efficiency and optimal resource use. MITA solutions are selected through advanced software in order to fit the plant characteristics.

Quick pay-back. Pre-selection performed together with the client, based on their project requirement.

Industry 4.0. Possibility of control, monitoring and data collection on company management system.

How it Works

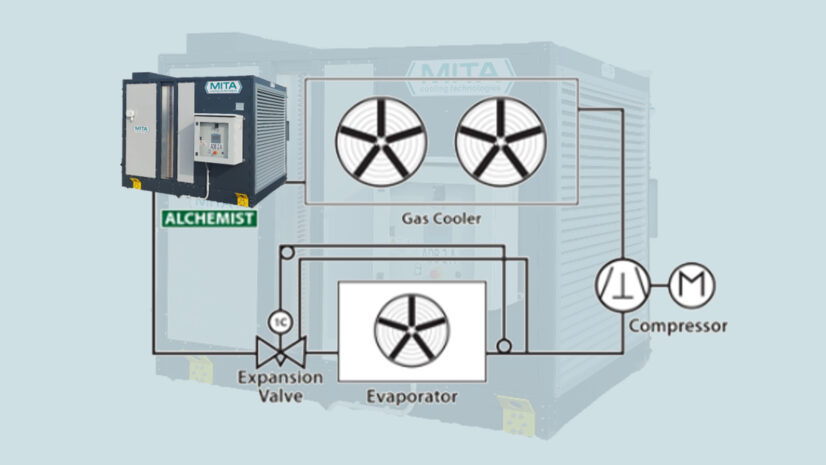

Alchemist combines the adiabatic cooling principle with refrigerant fluid subcooling to increase system efficiency. It is installed downstream of the condenser and/or gas cooler.

- Dry operation: external air is drawn in and conveyed onto the finned coils. The humidification process is deactivated, no water is present and the humidifier pack is dry.

The subcooling readings by temperature probes modulate fan speed to optimise power use. - Adiabatic operation: external air is drawn in and passed through the humidifier pack (protected inside the machine). The adiabatically cooled air (therefore at a lower temperature than the external air) is conveyed to the finned coils thus increasing the frigorific fluid subcooling. The subcooling readings by temperature probes modulate fan speed and adiabatic cycles to minimise power/water use.

Patent MITA 17194148.7.

Ask for InformationTechnical Features

- Savings in electricity compared to systems with only gas coolers.

- Water saving compared to the solution with only adiabatic gas cooler.

- All models are completely preassembled and equipped with an electrical panel (PLC that allows continuous optimization).

- Easy installation even in existing systems (retrofit).

- Each machine is accessible for inspections and maintenance of internal parts.

- EC plug fan.

- Finned coil.

- Humidifier pack with high water retention capacity made of flocked PVC (very short wetting cycles).

Environmental and economic sustainability of each MITA adiabatic subcooler

- Minimal use of water (only for adiabatic operation), useful for facilitating heat transfer (i.e., cooling of the process fluid).

- Optimized energy use (higher efficiency due to adiabatic supply).

- Falls within the product categories that MITA is able to regenerate.

- Indication of “carbon footprint” from the MITA team.

MITA realizations with adiabatic subcoolers

Alchemist Subcooler for Efficiency in a Refrigeration Unit

A store in the province of Vicenza has achieved a significant improvement in the performance of a CO2 refrigeration system, with energy and cost savings: this is thanks to Alchemist, a plug-and-play subcooler that can be easily integrated into existing systems.

Learn MoreAdiabatic Subcoolers in Supermarkets in Northern Italy

Sustainability without loss of performance: this was the challenge of a large-scale retail player with many supermarkets in northern Italy to which MITA supplied several Alchemist adiabatic subcoolers.

Learn MoreTools to help you choose

Cooling Advisors

Preliminary plant evaluation

Tailor-made design

Your Plant Needs

Newsletter

Subscribe to MITA newsletter and stay updated on technical solutions for industrial and civil cooling and get to know our offer.