Cooling Tower

“It is a heat rejection device that rejects waste heat to the atmosphere through the cooling of a water stream to a lower temperature. Cooling towers may either use the evaporation of water to remove process heat and cool the working fluid to near the wet-bulb air temperature or, in the case of closed circuit dry cooling towers, rely solely on air to cool the working fluid to near the dry-bulb air temperature” (Source: Wikipedia).

- Centrifugal cooling tower: device that uses a centrifugal fan to move the air which is necessary to perform forced evaporation. Generally preferred when there are noise problems, need for air ducting or when sound-absorbing silencers are needed.

- Closed-circuit cooling towers. Tower in which the process fluid which is cooled (often not water, but a cooling fluid) does not come into contact with the cooling water. This is distributed on the outer surface of a tube-bundle or of linked plates and circulates between the distributor and the basin.

- Crossflow cooling towers (against the current). Towers in which the air flow goes in opposing directions.

- Counterflow cooling towers. “In a counterflow design, the air flow is directly opposite to the water flow. Air flow first enters an open area beneath the fill media, and is then drawn up vertically. The water is sprayed through pressurized nozzles near the top of the tower, and then flows downward through the fill, opposite to the air flow” (Source: Wikipedia).

- Factory-assembled cooling tower: small and medium-sized, totally factory assembled in 2 or 3 main sections with dimensions that are compatible for road or sea transport. No assembly time or a few days for modular systems.

- Field-erected cooling tower. Generally large, in order to reduce transport costs. It is transported completely disassembled and assembled directly at the installation site. Assembly times are roughly variable between 20 and 60 days.

- Mechanical draft cooling tower. Evaporative cooler in which the water is cooled by partial evaporation through contact with a mechanically driven air stream.

- Open-circuit cooling towers. Evaporative system that cools water through direct exchange with air.

Our range of applications

Snowmaking Plants

Food Industry

In the food industry, cooling systems play a crucial role in preserving finished product quality and ensuring business continuity. MITA Cooling Technologies’ cooling technologies, such as closed-loop evaporative towers and adiabatic dry coolers, ensure precise and consistent temperatures for delicate food processes without compromising the safety and purity of process fluids.

Metalworking

Metal processing requires reliable, high-efficiency cooling systems to maintain stable temperatures during processes such as casting, rolling, and stamping. MITA Cooling Technologies offers advanced industrial cooling solutions: evaporative towers, dry coolers, adiabatic systems supported by parameter control panels. Reliability, precision, resource optimization: the cooling systems the metal processing industry needs.

Chemical and Pharma

In the chemical and pharmaceutical industries, temperature control is crucial to ensure the quality and safety of production processes. MITA Cooling Technologies offers advanced evaporative, open- and closed-loop cooling solutions designed for critical and aggressive environments. Our systems, including corrosion-resistant fiberglass cooling towers, ensure operational continuity, long life and adaptability to industry-specific thermal regulation requirements. With extensive industry experience, MITA is the ideal partner for optimizing cooling processes in the pharmaceutical and chemical industries.

Textiles and Tanneries

Textile and tanning industries require reliable and specific cooling systems for each production step: an example is the drying of leather in tanneries, carried out by vacuum pumps: the liquid ring of these tools is cooled by evaporative tower. MITA Cooling Technologies offers tailored solutions that include durable evaporative towers capable of handling dirty water and varying temperatures. Efficiency, durability and energy optimization to meet the needs of these industries.

Paper Mills

Le cartiere richiedono un raffreddamento efficiente per gestire le elevate portate di acque spesso sporche, contaminate da residui di cellulosa. MITA Cooling Technologies offre soluzioni di raffreddamento in vetroresina non-corrodibile, compatte o modulari e containerizzabili, ideali per ottimizzare i costi e agevolare il trasporto a lunga distanza. Torri di raffreddamento a circuito aperto e chiuso garantiscono performance costanti, facilità di manutenzione e resistenza all'intasamento.

Plastics and Rubber

Plastic and rubber processing requires specific cooling processes to ensure high productivity, finished product quality and temperature control during molding, extrusion and mixing. MITA Cooling Technologies offers advanced solutions-from chillers to adiabatic cooling systems-that optimize the cooling of molds, hydraulic components and oils, ensuring reliability and energy savings.

Industrial Wastewater

Multiple industries have a cross-sectoral need to cool wastewater from their production processes: these include textile, paper, and food companies. In this area, it is best to use evaporative towers with anti-clogging exchange packs for dirty industrial water. MITA offers efficient and sustainable cooling solutions, with evaporative towers designed to ensure long life even with dirty water and high flows.

Mechanical Industry

The mechanical industry includes the most diverse sectors, in addition to metal and plastic processing: compressors and test benches are significant examples. Required temperature differences and water quality vary greatly depending on the industry: evaporative cooling towers can be used, preferably open-circuit ones (with exchange packs for dirty or clean water depending on the context) and adiabatic coolers for consumption optimize.

Oil & Gas

MITA Cooling Technologies provides robust and efficient cooling solutions for the oil & gas industry. They are also optimized for intensive process cooling needs and resistance to extreme operating conditions. The PMM and PME-XL modular towers, together with the PU field-mounted towers, address the need for high flow rates, ease of installation and maintenance in complex environments, ensuring high performance and operational continuity even in harsh environments.

Hospitals and Healthcare

In the healthcare sector, industrial cooling is critical to ensure the proper operation of critical facilities such as HVAC systems and medical equipment. MITA Cooling Technologies offers quiet, low-maintenance solutions, such as cooling towers and dry coolers, designed for hospitals and clinics. The goal? Reliable performance, reduced operating costs and acoustic comfort.

Offices

Low noise levels to ease daily life: this is the “must” of the cooling circuits attached to the air conditioning systems in the offices. Configurations suitable for restricted or peculiar spaces are also often required: the ideal are open circuit cooling towers with sound-absorbing technologies, possibly equipped with versatile centrifugal fans.

Shopping Centers

The air conditioning systems in shopping centers must ensure low noise levels: the same goes for the attached coolers. Therefore, the engineering firms and plant installers are concerned with installing cooling solutions with sound-absorbing technologies, mostly evaporative. A further plus is the need to place the machine in confined spaces.

Tertiary Sector

Cinemas, theaters, buildings for public entertainment have the same needs as offices: the cooling units, attached to the air conditioning systems, must be silent and adapt to small spaces: also in this case, open-circuit cooling towers with sound-absorbing technologies are ideal. Centrifugal fans ensure space adaption, while non-corroding fibreglass extends product lifecycle.

Cold Chain

Foodstuff storage at temperatures below zero can be implemented through different types of natural or non-natural refrigerants: evaporative or adiabatic condensers can be indicated, depending on whether the company is focused on performance or resource use optimization. Low noise solutions are often appreciated.

Refrigeration in the Food Sector

Refrigeration in the food sector is linked to production lines in food & beverage: the optimization of efficiency and resources (water and energy) are the most requested needs by customers. Evaporative and adiabatic condensers must be able to manage different refrigerant gases based on project requirements.

Large-Scale Distribution and Supermarkets

Supermarkets and large-scale distribution are increasingly attentive to environmental sustainability: hence the choice to use natural refrigerants for chillers. In these cases, the adiabatic subcooler patented by MITA guarantees an extra step in efficiency: a solution that can be easily integrated into the system.

Cogeneration and Trigeneration

Datacenter

La nostra gamma di prodotti

Adiabatic Dry Coolers

Very little cooling water, only that necessary for humidification of the adiabatic section according to environmental conditions. Simple mains water that does not require any specific treatment. Efficient system (cooling efficiency), even during the hottest times of the year.

Open-Circuit Cooling Towers

MITA's open evaporative towers are known for their ease of use and extremely long life cycle (we have machines in operation for over 40 years). Easy to install and maintain. By forced evaporation small amounts of water (evaporative cooling), cooling towers are an extremely efficient, economical and compact solution.

Refrigerant condensers

Everything you find in closed-loop cooling towers, except that the tube bundle can condense a wide variety of refrigerants. Many references of NH3 (ammonia) condensers in industrial refrigeration, where these MITA systems are valued for performance, reliability, and easy operational management.

Air Coolers (Dry Coolers)

Ease of installation and use. Industrial dry coolers are the right solution for cooling fluids that do not require lower process temperatures than outside air, or for those who do not wish to use water as a cooling carrier, preferring only ambient air.

Closed-Circuit Cooling Towers

Also with these coolers, again thanks to the principle related to forced evaporation of water, we can offer extremely efficient systems. Compared with open evaporative towers, the fluid to be cooled remains protected within a tube bundle. Easy installation and maintenance.

Industrial Chillers

Mechanical or compression chillers, systems that allow fluids to be cooled even below 0°C with point operating temperatures. MITA's industrial chillers are mostly air-cooled, with advanced electronic management from a 4.0 perspective.

Integrated Systems

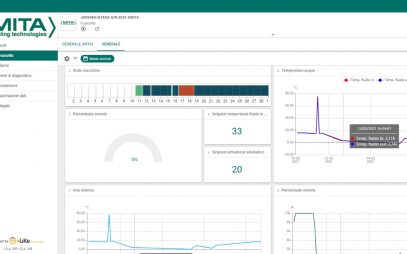

A set of advanced tools to monitor the industrial cooler everywhere, optimize its performances and resource use, integrate it truly with all production processes.

MITA Remanufactured Industrial Coolers

MITA customers can also consider purchasing remanufactured cooling technologies. One more solution with many advantages and extremely sustainable.

Spare Parts

Keep your cooling system efficient and safe by replacing its obsolete components. The result? It will look like a newly installed technology.

Your Plant Needs

News correlate

Plast 2018, Milan May 29 th – June 1st

MITA Cooling Technologies has taken part to Plast 2018 (May 29th - June 1st).

Mostra Convegno Expocomfort, Milan 13-16 March 2018

MITA took part in 38° MCE (Milan Fair – Rho, 13-16 March 2018).

The group “Cooling Towers” in Assoclima has been re-formed

Among the aims of the group there is the institutional presence at Italian

Newsletter

Subscribe to MITA newsletter and stay updated on technical solutions for industrial and civil cooling and get to know our offer.