1. Installation context and requirements

In 2020, a major Spanish coke producer located in Asturias faced the need to optimize the cooling of its production processes.

With an annual capacity of more than 100,000 tons, the company stands out for its versatility in product delivery and attention to raw material quality. The main challenge was related to water scarcity in the installation area, a critical issue that required innovative solutions to ensure water savings and energy optimization.

The installation involved TORRAVAL Cooling, a subsidiary of MITA Cooling Technologies in the Iberian Peninsula and a partner of the group, with the support of a local installer. The client needed a system capable of cooling water with an inlet temperature of 36°C and an outlet temperature of 30°C. The climatic conditions of the installation area: outdoor air temperature of 29.4°C (dry bulb) and 22.3°C (wet bulb). The required power output was 430 kW.

2. Proposed Solution

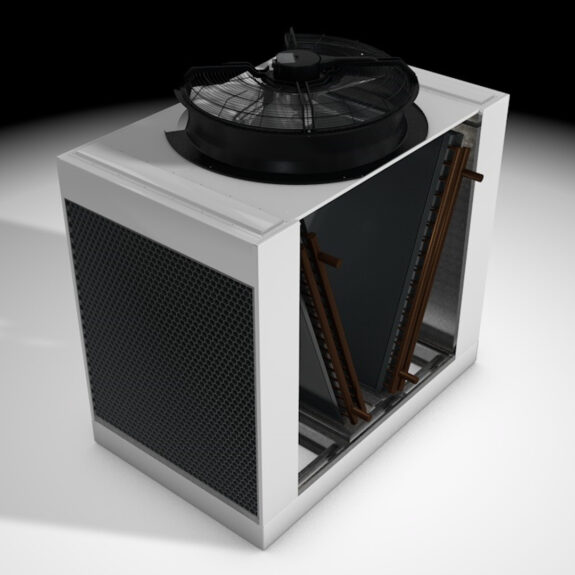

To meet the specific needs of the customer, MITA Cooling Technologies and TORRAVAL Cooling provided an adiabatic dry cooler model PAD V 3/5 with 123 circuits. This technology is designed to operate in both dry mode and adiabatic mode: the latter mode, ideal for hot times of the day and year, allows pre-cooling of outside air to improve performance.

Distinctive features of the system provided include:

- Highly impregnating and rot-resistant PVC flocked adiabatic pack.

- Standard PLC control panel, with customizations asked by the client, allowing automated optimization of operation and switch between dry and adiabatic modes.

- Modbus communication protocol for remote monitoring and performance control.

- Lower system enclosure, which was mounted on a 7-meter platform for easy installation and integration into the existing system.

The adiabatic dry cooler was shipped directly from Italy to Spain, with transportation included in the service. The 36-month warranty further ensured the customer’s peace of mind.

3. Results and key success factors

The installation of the adiabatic dry cooler has enabled the coke producer to fully meet its cooling needs while providing significant water savings. The PLC control panel enables constant and continuous parameterization of performance, optimizing resource utilization and thus minimizing operating costs.

Key success factors include:

- Rightsizing of the system for the climatic data of the installation area: a customized solution based on configuration via in-house software.

- Significant water savings due to the very nature of adiabatic technology.

- Reliability and high performance, supported by the superior adiabatic package and system versatility.

- Dedicated technical support and close cooperation between MITA Cooling Technologies, TORRAVAL Cooling, and the local installer.

This delivery not only met the customer’s technical and environmental requirements, but also strengthened the reputation of MITA Cooling Technologies and TORRAVAL Cooling as reliable partners in the steel industry.

Ask for Information