1. Installation context and requirements

In 2024, a major bottling company based in Mexico embarked on a cooling project for its production lines, also aiming to optimize energy efficiency and reduce water use within its plant. The company specializes in sustainable packaging for the beverage industry and has a significant presence in Latin America, striving to promote circular economy practices.

The client’s primary requirements included cooling the bottling lines, in a climate context characterized by an ambient air of 29°C and a wet bulb temperature of 14.6°C. The requirement also included maintaining a fluid outlet temperature of 30°C, with a total cooling capacity of about 2,300 kW.

A solution was needed that could support sustainability by reducing water and energy use.

2. Proposed solution

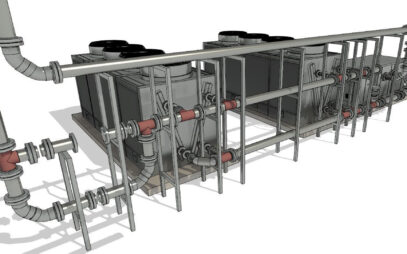

MITA Cooling Technologies, together with its national distributor Innotec MC, proposed the installation of two PAD-V series adiabatic dry coolers equipped with advanced technologies to optimize energy consumption and operational efficiency. Three units were installed:

- one adiabatic dry cooler PAD-V H 4/5 Q, with four fans and a thermal output of 900 kW;

- two PAD-V H 3/6 T adiabatic dry coolers, with three fans and a thermal output of 680 kW per machine.

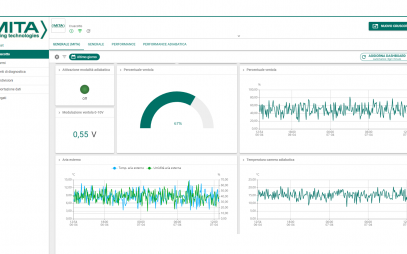

The chosen technology, in addition to meeting the cooling requirements, included the MITA IOT system, a platform for remote management of the equipment. This solution ensured continuous supervision and precise monitoring of operating parameters, further improving plant efficiency.

Among the constructional strengths of the dry coolers are the durable and highly impregnable PVC flocked adiabatic pack, which prevents the risk of rot, and the presence of removable walls for easy internal inspection and maintenance of the systems.

The installation also included ongoing technical support from MITA Cooling Technologies and Innotec MC, both during the pre-installation and operational phases. An additional precaution was the provision of recirculation kits to optimize the use of the equipment, especially in the context of overseas transportation.

3. Results and critical success factors

The first crucial aspect of the delivery was the reduction in resources used, thanks to the electronically controlled motor-fan units, which optimized energy use, and the PVC adiabatic pack, which ensured greater efficiency in pre-cooling the outside air (the heat-disposal carrier) during the adiabatic mode of operation.

In addition, the wide range of solutions offered by MITA allowed the Mexican company to choose the most appropriate option for its specific project needs, combining a focus on sustainability with maximum operational efficiency.

Ask for Information