Cooling Tower: Operation and Use

A complete guide on how open and closed evaporative towers work. Cooling tower components. Water treatment in cooling towers. Choosing a cooling tower manufacturer.

What is a Cooling Tower?

“A cooling tower is a device that rejects waste heat to the atmosphere through the cooling of a coolant stream, usually a water stream, to a lower temperature. Cooling towers may either use the evaporation of water to remove process heat and cool the working fluid to near the wet-bulb air temperature or, in the case of dry cooling towers, rely solely on air to cool the working fluid to near the dry-bulb air temperature using radiators.” (Definition source: Wikipedia)

How Does a Cooling Tower Work?

Cooling Towers: What They Are, How They Work, How to Maintain Them

How evaporative cooling towers work, performance, internal components, industrial and HVAC applications. Water maintenance and treatment.

Cooling Towers: Components and Materials

The quality of the water to be cooled significantly affects both the choice of constructive materials and fill pack material.

Cooling Tower Water Treatment: what to know

Here a complete guide on how to establish an optimal cooling tower water treatment (systems and tricks). What is the aim of an automatic make-up system? Which is the role of a proper chemical treatment? How to maintain the circulating water at optimal operating limits? All questions your process cooling advisor can answer.

Design and Production of Cooling Towers

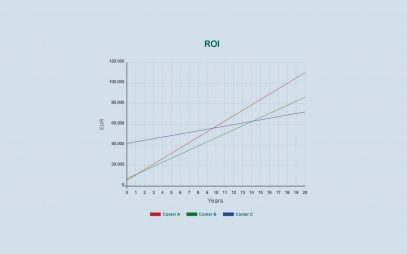

Resource and Efficiency Optimization of Cooling Systems: How to Assess It

The comparison between different cooling technologies: a calculation software can now fulfill this task based on real climatic data.

Cooling Tower Manufacturer: how to find the Supplier Who best meets your Needs

It is not always easy to find your way around the jungle of cooling tower manufacturers as a buyer. See some advice.

Fibreglass cooling towers: why are they still up-to-date?

Many manufacturers of open and closed circuit cooling towers, even large ones, continue to use fibreglass: Giorgio Lorenzetti explains why.

Applications of Cooling Tower

Cooling Systems in Food Industry

In the food industry, cooling systems play a crucial role in preserving finished product quality and ensuring business continuity. MITA Cooling Technologies’ cooling technologies, such as closed-loop evaporative towers and adiabatic dry coolers, ensure precise and consistent temperatures for delicate food processes without compromising the safety and purity of process fluids.

Cooling Systems for the Chemical and Pharmaceutical Industries

In the chemical and pharmaceutical industries, temperature control is crucial to ensure the quality and safety of production processes. MITA Cooling Technologies offers advanced evaporative, open- and closed-loop cooling solutions designed for critical and aggressive environments. Our systems, including corrosion-resistant fiberglass cooling towers, ensure operational continuity, long life and adaptability to industry-specific thermal regulation requirements. With extensive industry experience, MITA is the ideal partner for optimizing cooling processes in the pharmaceutical and chemical industries.

Cooling Technologies for Offices

Low noise levels to ease daily life: this is the “must” of the cooling circuits attached to the air conditioning systems in the offices. Configurations suitable for restricted or peculiar spaces are also often required: the ideal are open circuit cooling towers with sound-absorbing technologies, possibly equipped with versatile centrifugal fans.

Focus: cooling technologies for datacenters

With the increase in computing resources required, whether by massive use of the Internet or new applications of artificial intelligence, datacenters are becoming increasingly large and energy intensive. Cooling technologies must therefore reconcile performance with water and energy savings: from efficient cooling towers to structurally simple dry coolers to adiabatic dry coolers and chillers, the focus is always on the needs of the individual project.

Plants with Cooling Towers: Some Projects

- Paper Mills

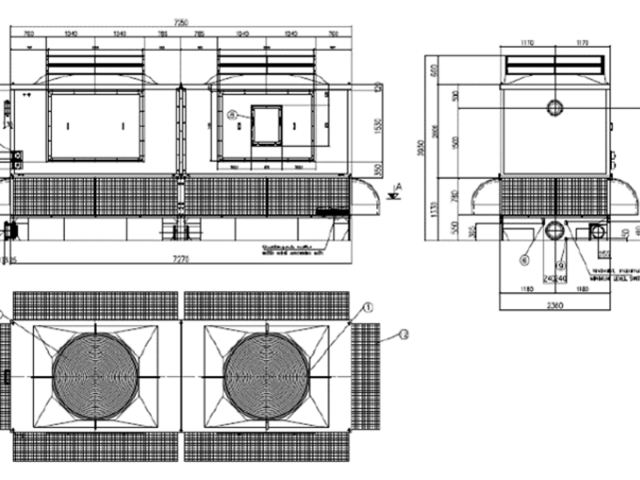

Large Industrial Towers for a Paper Mill in Sweden

Maxi size, minimal noise. The PME cooling towers supplied to CAMpreq, installed at a paper mill in central Sweden, combine appropriate design with high water flow rates and solutions to contain noise levels.

Learn More

- Food & Beverage Industry

Industrial Cooling Tower for Coca Cola in Kiev

A MITA cooling system serving one of the world's most celebrated multinational food & beverage companies: the Kiev-based Coca-Cola now uses a PME-E evaporative tower for its production facilities.

Learn More

- Food & Beverage Industry

The plus of fiberglass for corrosive industrial environments

The common factor in all MITA evaporative towers is fiberglass, a plastic material that is excellent for ensuring durability. It is a technical feature also successfully tested by a major Russian salt producer.

Learn More

Evaporative Cooling Towers: Solutions on the Market

PME-E Open-Circuit Evaporative Cooling Tower

A light and non-corrodible open-circuit evaporative cooling tower: process industry and HVAC operators will be able to count on its multiple versions and ease of transport and installation.

PU Field-Erected Cooling Tower

The PU series field-erected industrial cooling tower can serve very large plants: especially oil & gas, chemical and power generation. Available for all industrial water. Different materials are supplied according to project needs: concrete, steel, fiberglass and pultruded.

PMS Evaporative Open-Circuit Cooling Tower

It is a cooling tower for industries of any type and for any water quality: very compact, self-supporting, light and long-lasting non-corrodible fiberglass structure.

Newsletter

Subscribe to MITA newsletter and stay updated on technical solutions for industrial and civil cooling and get to know our offer.