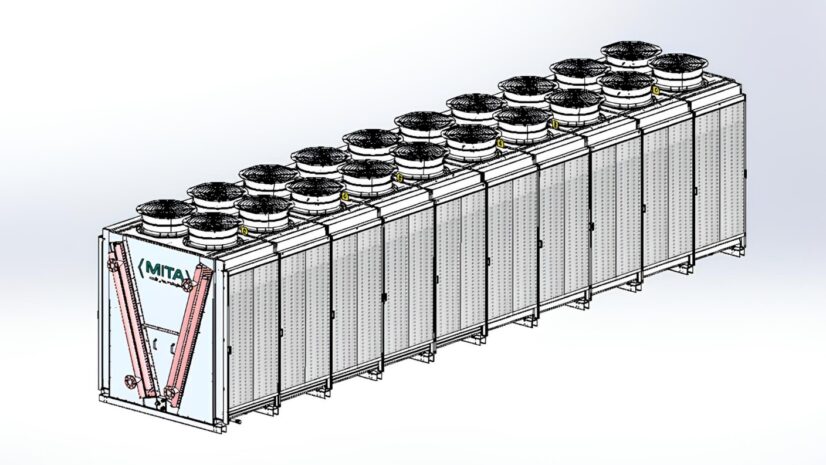

MITA Cooling Technologies expands the Range of PAD-XL Adiabatic Dry Coolers up to 2,500 kW

MITA Cooling Technologies strengthens its offering of industrial cooling solutions with the extension of the PAD-XL adiabatic cooler range, now available with a cooling capacity of up to 2,500 kW. The new configuration includes up to 20 fans, arranged in two rows, and a total length of 11.6 meters.

MITA thus aims to meet the needs of large plants and overseas markets with high efficiency demands.

1. An adiabatic cooler for systems of all sizes

The PAD-XL W is an ideal solution for those seeking an efficient system with low water use and high performance, even in the most challenging weather conditions.

This cooler is a viable alternative to classic dry coolers, thanks to its adiabatic technology that allows alternating dry operation and pre-cooling of ambient air with little wetting water. All this while optimizing the use of the resources employed.

MITA’s PAD-XL adiabatic dry coolers are an excellent support for heat dissipation of systems of all types thanks to a number of special features.

- Minimal water use: short wetting cycles to humidify the adiabatic section, only when necessary. A wetting water recovery system is integrated.

- Optimization of energy use: the intelligent management system automatically adjusts the operation of the fans, always ensuring the best ratio between performance and resources used.

- Easy installation and transport: plug-and-play design allows it to be easily moved on standard trucks and quickly installed.

- Guaranteed year-round performance: thanks to advanced operation logic, PAD-XL W ensures optimal performance even during the hottest times of the year.

- Easy maintenance: safe and direct access to all essential parts of the system.

2. How the adiabatic cooler works

Adiabatic coolers, also known as adiabatic dry coolers, cool process fluids using ambient air.

At times of high temperature, air can be pre-cooled through a controlled wetting cycle, thus improving system efficiency. PAD-XL W adopts this advanced technology to minimize water use and optimize thermal efficiency.

All about Adiabatic Cooling

Learn more3. MITA Cooling Technologies: innovation for every need

MITA Cooling Technologies has been designing and manufacturing industrial cooling solutions for more than 60 years, with a wide range of products. These include:

- open-loop and closed-loop cooling towers,

- dry coolers,

- adiabatic dry coolers,

- industrial process chillers.

The company stands out for its constant search for innovation and sustainability, offering state-of-the-art systems for “green” cooling of plants in various industries.

With the expansion of the PAD-XL range, MITA Cooling Technologies confirms its commitment to providing efficient and scalable solutions for the most complex cooling needs.

—

We are available for any inquiries or questions you may have about our cooling systems for the process industry, HVAC and industrial refrigeration.

For information: export@mitact.it

Ask for InformationNews correlate

PAD-XL Adiabatic Dry Cooler: the New Video Presentation

Tommaso Fontana, Sales Manager of MITA Cooling Technologies, explains the operation of PAD-XL: the adiabatic cooler designed for heat dissipation

New PME XL Cooling Tower: Power and Lightness in a Single Cell

MITA Cooling Technologies expands its range of cooling towers with the new PME XL: an open-loop tower offering up to

Welcome to the headquarters of MITA Cooling Technologies: corporate video

A visit to the place where your cooling needs are addressed through innovative process and HVAC-R systems. Open and closed

Newsletter

Subscribe to MITA newsletter and stay updated on technical solutions for industrial and civil cooling and get to know our offer.